Our weighing systems

We have three weighing systems for different uses

Väg i farten - utan stopp

Dynamisk vägning som sparar tid och ökar effektiviteten.

Smidig datahantering

Trådlös överföring, PDF-kvitton & API-koppling – allt integrerat.

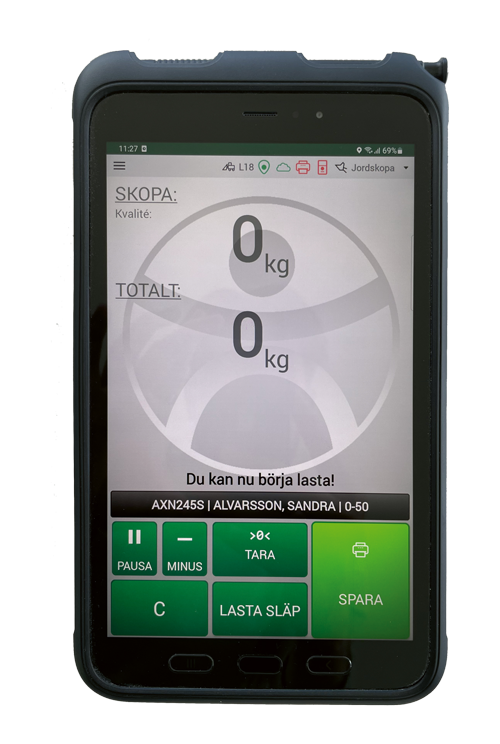

Smart och enkel att använda

Intuitiv skärm, GPS-spårning och säker startspärr.

Guide for usage

Cooperation with NCC

Lundaman's new weighing system P2 helps our customers take a step into the future by digitizing their loading. Here you can see a little about our collaboration with NCC, where together we develop the scale to make everyday life more efficient, both for machinists and in the office when invoicing.

Here you meet supervisor Erik Goude and machinist Mattias Johansson, who talk about their everyday life and how one of NCC's many Lundaman P2s helps them load correctly.

Advantages of using a Lundaman weighing system

Using a weighing system for wheel loaders or forklifts offers several advantages that improve efficiency, accuracy and safety in material handling and weighing. Here are some of the benefits of using our systems:

GPS TRACKING

Through GPS tracking, you can easily track a specific load from the office. When the operator performs a lift, location information is logged and automatically sent to Lundaserver. You get the loading through a satellite image where you see in which zone each lift is registered.

IMMOBILIZER

For those who want security over both machine and material. Each driver receives a personal code that is entered in the scale to be able to use the machine, all lifts that are made are registered on the respective driver. Log of everything that happened is handled with ease on LUNDASERVER 2.0.

SEVERAL DIFFERENT REGISTERS

Information is selected by the operator in a clear format with an on-screen keyboard and flexible search function for easier selection. When the truck returns, there are quick selections for previously selected fields.

Driving orders also come as standard for those who want to send completed orders directly to the scale.

TRANSFER OF DATA

Now you can get your desired information directly to the office. Work with the information directly on LUNDASERVER 2.0 or integrate with business systems. We also offer the option of API connection for an automated and digital workplace.

WAREHOUSING / QUICK SELECTION

A “swipe” will take you to the storage run. Here you can easily choose between different materials directly on the screen. You get an overview both in the machine and in the office. Detta läg kan du också använda till mycket annat, kontakta oss så berättar vi mer om hur detta hade kunnat effektivisera er arbetsplats.

Weighing systems for forklifts

Lundamans truckvåg erbjuder en bred lösning med allt från att endast visa vikten till att arbeta med register för att rapportera in till kontoret.

We have functions that make your operation easier, such as quick selection for different types of material during production runs or quick selection for returning customers.

You can print the load information directly in the cabin or send digital receipts.

Weighing system for wheel loaders

Lundamans hjullastarvåg strävar efter enkelhet, alltid med få knapptryck. Lättanvänd dynamisk vägning utan stillestånd.

With modern features like digital management and receipt printing.

Reliable support to avoid downtime.